VDF

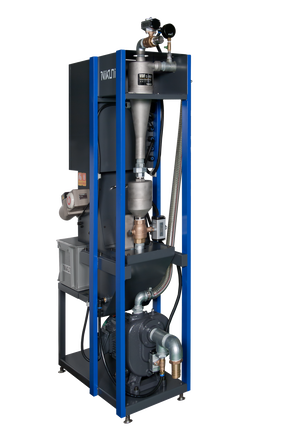

NAX-CS

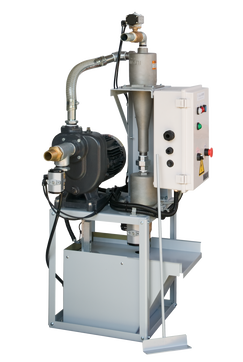

LAX (Hydro Vacuum Cleaner)

New C-Cat

C-Cat

SLX

C-Jaguar

BAX

Click at below products to view more:

Centrifugal coolant fiiltration. No waste! No filtration media! No maintenance!

The Vortex Dynamic Filter is a media free coolantfiltration system which achieves filtration through centrifugal force eliminating the need for disposable paper or cartridge filters.

Features

- Filter replacement is not necessary as filtration is achieved through centrifugal force

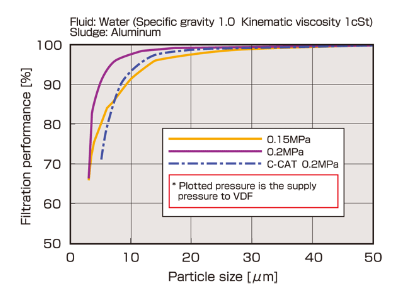

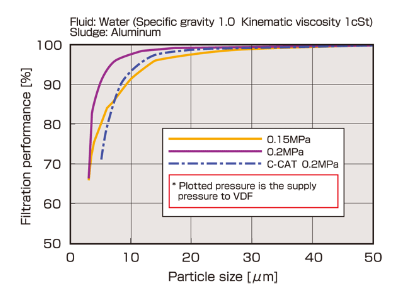

- Can remove 90% of 10μm sludge for water based coolant

- No bubbles or foam is produced

- Contaminants are concentrated in the sludge pod and once removed they cannot return to the coolant tank

The Vortex Dynamic Filter is a media free coolantfiltration system which achieves filtration through centrifugal force eliminating the need for disposable paper or cartridge filters.

Features

- Filter replacement is not necessary as filtration is achieved through centrifugal force

- Can remove 90% of 10μm sludge for water based coolant

- No bubbles or foam is produced

- Contaminants are concentrated in the sludge pod and once removed they cannot return to the coolant tank

Download catalog

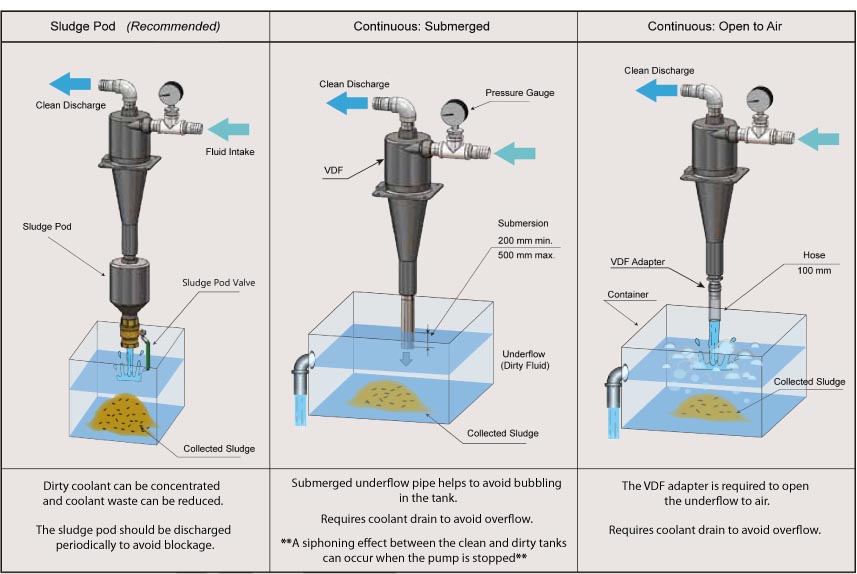

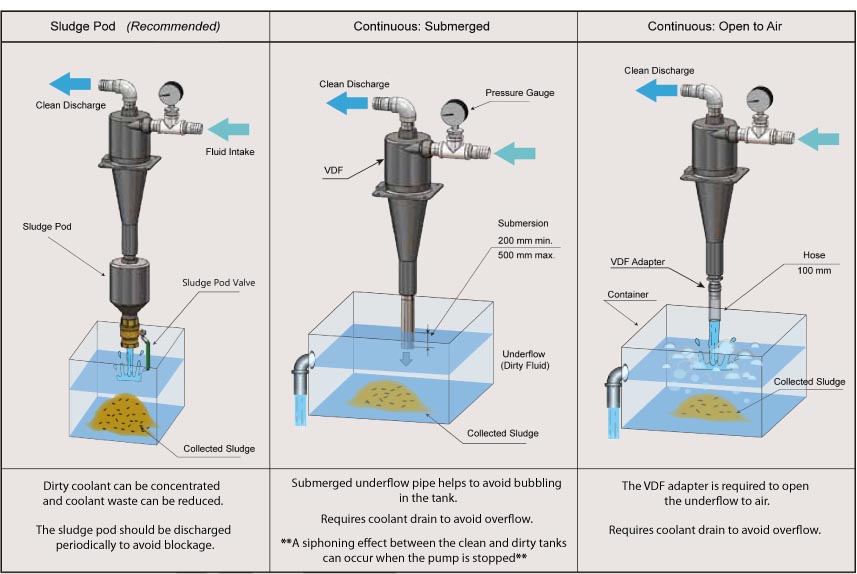

Filtration performance Underflow Options

Underflow Options

The Vortex Dynamic Filter is a media free coolantfiltration system which achieves filtration through centrifugal force eliminating the need for disposable paper or cartridge filters.

Features

- Filter replacement is not necessary as filtration is achieved through centrifugal force

- Can remove 90% of 10μm sludge for water based coolant

- No bubbles or foam is produced

- Contaminants are concentrated in the sludge pod and once removed they cannot return to the coolant tank

The Vortex Dynamic Filter is a media free coolantfiltration system which achieves filtration through centrifugal force eliminating the need for disposable paper or cartridge filters.

Features

- Filter replacement is not necessary as filtration is achieved through centrifugal force

- Can remove 90% of 10μm sludge for water based coolant

- No bubbles or foam is produced

- Contaminants are concentrated in the sludge pod and once removed they cannot return to the coolant tankDownload catalog

Filtration performance

Underflow Options

Underflow Options

|

|

|

|

|

System features

| Model | Description | Sludge pod valve | Supernatant return | Auto-srop when full | sludge tank w/scraper | Gather-up conveyor |

| C-CAT | Manual | Manual | x | x | x | x |

| C-JAGUAR | Semi automatic | Automatic | O | O | O | x |

| NAX-CS Ⅱ | Fully automatic | Automatic | O | O | N/A | O |

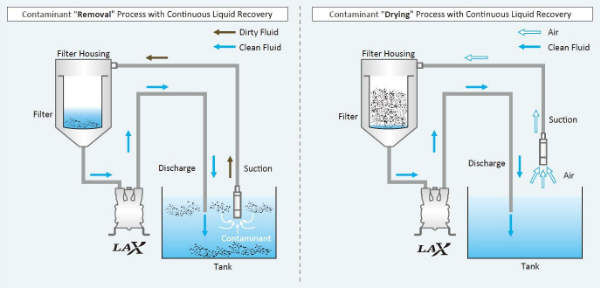

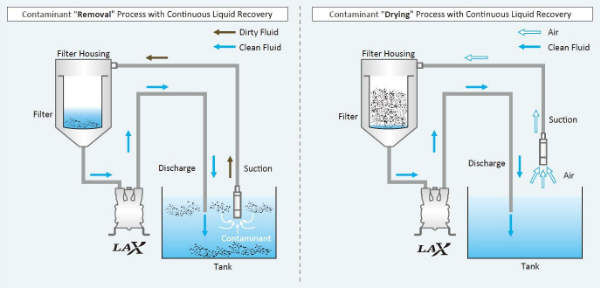

The LAX is a portable wet-to-dry filtration cleaner and can even filter coolant while the machine is in operation.

Easy Operation

Runs on single phase power and is portable for use with multiple machines

No Downtime

The LAX does not reduce tank coolant level, therefore it can be used while the machine is running

Capable of drawing in air

As the pump can draw in air the unit is capable of drying sludge after cleaning the tank for easy disposal. There is no need for external air supply

Easy Operation

Runs on single phase power and is portable for use with multiple machines

No Downtime

The LAX does not reduce tank coolant level, therefore it can be used while the machine is running

Capable of drawing in air

As the pump can draw in air the unit is capable of drying sludge after cleaning the tank for easy disposal. There is no need for external air supply

Download catalog

Flow Diagram

Case study 1. Centerless grinding machine Material : Steel Machine : Centerless grinding machine with 100 L tank Sludge collection time : 10 min Dehydration time : 10 sec

Case study 2. : Running machining center Material : Aluminum Sludge collection time : 10 min Dehydration time : ~2 min

Easy Operation

Runs on single phase power and is portable for use with multiple machines

No Downtime

The LAX does not reduce tank coolant level, therefore it can be used while the machine is running

Capable of drawing in air

As the pump can draw in air the unit is capable of drying sludge after cleaning the tank for easy disposal. There is no need for external air supply

Easy Operation

Runs on single phase power and is portable for use with multiple machines

No Downtime

The LAX does not reduce tank coolant level, therefore it can be used while the machine is running

Capable of drawing in air

As the pump can draw in air the unit is capable of drying sludge after cleaning the tank for easy disposal. There is no need for external air supply

Download catalog

Flow Diagram

Case study 1. Centerless grinding machine Material : Steel Machine : Centerless grinding machine with 100 L tank Sludge collection time : 10 min Dehydration time : 10 sec

Case study 2. : Running machining center Material : Aluminum Sludge collection time : 10 min Dehydration time : ~2 min

Excellent liquid-solid separation performance with over 90% filtration of 10µm sludge in water based coolant, without the need for costly replacement filters.

Download catalog

Flow Diagram

| Model | Flow rate L/min / GPM | L (mm) | W (mm) | H (mm) | Weight (kg) |

| C-CAT M30 | 35 / 9.2 | 410 | 450 | 1300 | 67 |

| C-CAT M50 | 65 / 17 | 415 | 460 | 1340 | 69 |

| C-CAT M70 | 80 / 21 | 520 | 465 | 1340 | 77 |

| C-CAT M100 | 100 / 26 | 520 | 465 | 1355 | 82 |

| C-CAT M200 | 195 / 51 | 735 | 538 | 1870 | 125 |

| C-CAT M300 | 280 / 74 | 735 | 538 | 1903 | 130 |

(Semi-Automatic Type) Similar to the C-CAT but with the additional benefits of an automated purge system.

| Model | Flow rate L/min / GPM | L (mm) | W (mm) | H (mm) | Weight (kg) |

| C-JAGUAR-30LW | 30 / 8 | 406 | 720 | 1180 | 77 |

| C-JAGUAR-50LW | 65 / 17 | 415 | 725 | 1205 | 79 |

| C-JAGUAR-70LW | 75 /20 | 640 | 635 | 1205 | 87 |

| C-JAGUAR-100LW | 90 / 24 | 640 | 635 | 1240 | 92 |

| C-JAGUAR-200LW | 195 / 51 | 885 | 825 | 1935 | 145 |

| C-JAGUAR-300LW | 280 / 74 | 885 | 825 | 1970 | 150 |

(Fully-Automatic Type) The NAX-CS is fully automatic filtration system including automated purge and gather-up conveyor to remove settled sludge

| Model | Flow rate L/min / GPM | L (mm) | W (mm) | H (mm) | Weight (kg) |

| NAXCS 2-30LW | 30 / 8 | 440 | 800 | 1145 | 130 |

| NAXCS 2-50LW | 65 / 17 | 440 | 800 | 1560 | 136 |

| NAXCS 2 -70LW | 75 / 20 | 440 | 940 | 1560 | 147 |

| NAXCS 2 -100LW | 90 / 24 | 440 | 940 | 1600 | 152 |

| NAXCS -200LW | 195 / 51 | 810 | 1050 | 1865 | 235 |

| NAXCS -300LW | 280 / 74 | 810 | 1050 | 1900 | 240 |